AI, as it’s usually called, can be defined as the ability of machines to mimic cognitive functions, such as learning and problem-solving, that humans associate with other human minds. Computers can detect problems and work round them. Except, of course, when they don’t; as happened in 2016 when a Tesla car being driven in Florida failed to detect a lorry crossing its path, crashing and killing its human driver. He was partly to blame; but so was Tesla.

Creating a spark

Many high profile people have commented on this technology; some inspired and some fearful. Stephen Hawking the famous Theoretical physicist who passed away earlier this year believes “The development of full artificial intelligence could spell the end of the human race.”

Jack Ma the famous Chinese billionaire who founded Alibaba is more optimistic. “We should not fear AI…. For the last 30 years we made people like machine, in the next 30 years we will make machine like the people “. His call is to change the education system and for a move away from knowledge based teaching. And Google chief executive Sundar Pichai says: “AI will do more for humanity than fire or electricity”.

AI is nothing new. It’s been around for decades but what is different is the volume of data now available along with ‘Internet of Things’ (IoT), creating more connectivity between systems. The linking of systems and data sets together means the potential to harness change is very great.

How is AI changing shipping?

In this article we’ll be looking at the vessel, the port and the office. In the best case scenario, AI has the potential to help us do our jobs better. In the worst, replace us humans altogether. So how much impact will it make?

The Vessel

The pinnacle of AI shipping will be an unmanned vessel that safely moves a cargo from A to B with no human being on board or the vessel being controlled remotely. Impossible? Well, the technology is already here. Rolls Royce remotely navigated the worlds’ first remote controlled vessel, the 28 meter Switzer Herod in Copenhagen Harbour. It demonstrated vessel navigation, situation awareness, remote control and communication systems.

If you look at similar industries, they’ve been ahead of the game for some years. In aviation a plane for example, can take off, fly to its destination and land without human intervention. Would you want to get on board a plane without a pilot?… probably not. This opens the larger question of safety, which is the complex issue holding this technology back. The Switzer Hermod passed many safety requirements but it would take a long time to create the legal framework to deploy this type of technology every day.

The other burning question is: “is it necessary?” Is there an op cost saving? If you could replace your 30 crew on board, would the expenditure in technology offset the cost of crewing a vessel.

Lonely at Sea?

DNV GL IACS chairman Knut Orbeck-Nielson explained his vision at London International Shipping Week last year. Now we have humans piloting the vessel; by 2020 we will move to assisted vessels helping the master and crew make decisions; by 2025 remote vessels; and finally autonomous vessels by 2035. There will be a gradual shift toward autonomous vessels but it will be step by step approach.

If you can aid the master with better decision making, then all the better, but most of the crew on a vessel is involved in maintenance. You would still want a crew on a vessel to keep in running efficiently and reduce time in port. Therefore the unmanned vessel is just a case of whether this will improve safety. Rolls Royce marine president, Mikael Makinen believes the future will be unmanned but the maintenance crew would be on other smaller support craft that go from vessel to vessel as they need repairs. Therefore, it is likely you will always have a seafarer, but the number of crew required will likely reduce but will not be eradicated.

The Port

The container terminal by nature creates repetitive tasks. Learning from the past can help your decision making for these tasks in the future. In the terminal operating systems, there is great potential to use AI technology.

Hamburg terminal

Ports are now partnering with large tech companies to realise AI capability. The Port of Rotterdam have teamed up with IBM and they are installing IoT sensors. The sorts of things they are measuring include weather, water, and communications data. The data will then provide insights into the port’s activities and may be able to help reduce wait times and select the best entry and exit times for the cargo ships.

One significant hurdle remaining for AI is the quality of data available. The well known phrase rubbish in rubbish out has been a stumbling block to developments. Unless you have solid information through the supply chain it will become very difficult to make decisions. Although part of the AI challenge is to use the data you have and extract the useful elements out of it, which as an industry we need to get better at doing.

All these developments will mean there is great scope to reduce waiting times in ports and increase efficiency. The ports which make the gains more quickly will have a distinct competitive advantage. It will free up vessels and increase the tonne days capacity of the shipping fleet. The application will be gradual as serious capital investment would be required. The large hubs will lead the way and the smaller ports will eventually need to catch up.

The Office

In January, a McKinsey & Company study found that about 30% of tasks in 60% of occupations could be computerised. The understanding AI potential is a very topical subject at the moment. Earlier this year it made the front page of the Economist with a large supplement section. The important message is that companies need to embrace this now or they will be left behind by their competitors. It often starts with small ideas and projects that give you incremental gains.

There could be negative consequences however, particularly in areas like the HR. When applying for a job, a company could feed your profile into a model to work out if you are the right person to hire. Certain factors like ‘length of commute’ might mean your longevity as an employee is statistically reduced and the computer decides you don’t get the job.

Our Experience

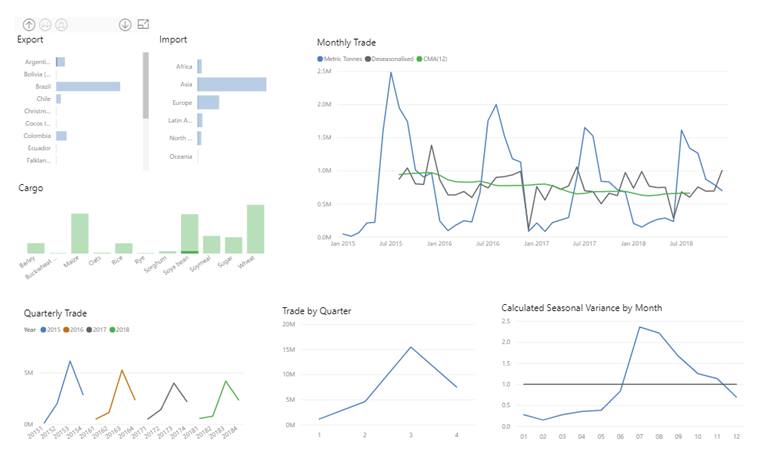

Tradeviews was started 6 years ago with the aim of improving maritime trade statistics. We had no idea what was possible back then but we realised we needed to start understanding the patterns of trade with the vast amounts of data available. We started applying AI techniques to better understand customs trade statistics. The tasks we performed included determining which sources are reliable, estimating holes in data series and producing a seasonally adjusted forecast of the future.

Soybean Cyclicality

With a consolidated dataset on trade we allow companies to identify trends relevant to them. In the example above we can see the last 3 years seasonal trend in Soybean trade from Argentina. In a recent move government changed the policy on tariff payment timings to encourage more deals from exporters. The unique insight provided by our data can give an analyst the right information to access the impact on future trades.

How we can help you with your next AI project?

Tradeviews has teamed up with ASI Data Science to organise roundtable discussion groups to help you imagine what areas of your business can be improved by AI technology. Recent projects ASI have been involved with include predictive vessel maintenance, container capacity management , smart container loading and fuel efficient shipping routes.

Heads together

If you are interested in joining our next discussion, then please do get in touch at by contacting Russell Thompson (russell@tradeviews.net).